VW electric flagship a slippery customer

/The Ioniq 6 and Benz EQE ‘aero club’ has a new member. Will Kiwis experience the ID.7?

INSIGHT into the effort Volkswagen has put into finessing the aerodynamics of an upcoming flagship of its electric car fleet to achieve an impressive range target has been shared.

The German appears highly assured the ID.7 sedan will come with a range of up to 700 kilometres, as measured on the WLTP scale now prioritised for New Zealand, due to ‘sophisticated aerodynamics’ that lend a drag co-efficient of 0.23.

That’s the best count of the ID. family and puts the car in the same ‘super slippery’ camp as two other electrics of similar ilk already here, the Hyundai Ioniq 6 and Mercedes-Benz EQE.

From the look of it, the BYD Seal just confirmed for NZ sale later this year, likely as a Tesla Model 3 price competitor according to talk from Mystery Creek national fieldays where it is on display, might also be a contender.

There is no word yet from Volkswagen New Zealand if ID.7 will eventually site above the ID.4 and ID.5 set to be on sale from September, and the refreshed ID.3 arriving next year.

Ostensibly, ID.7 is foremost for Europe and North America, however the brand has never ruled out a broader export plan and VW NZ media page continues to run stories of its development programme, which - on strength of the images shared by head office today - is now clearly nearing conclusion.

The almost five metre long car's aerodynamically favourable basic form, which also comes from it having a frontal area of 2.46 square metres, is not the only technical highlight.

ID.7 sits on the VW Group-shared bespoke electric underpinning, called the MEB model, also used by other ID models, plus the NZ-arriving Skoda Enyaq, Cupra Born and Audi Q4 and Q5. However, it is the first with a completely new, highly efficient drive generation.

Offering 210kW, it is the most powerful and highest-torque electric drive motor in a Volkswagen ID. model so far. The power variant is used in the ID.7 independently of the chosen battery size.

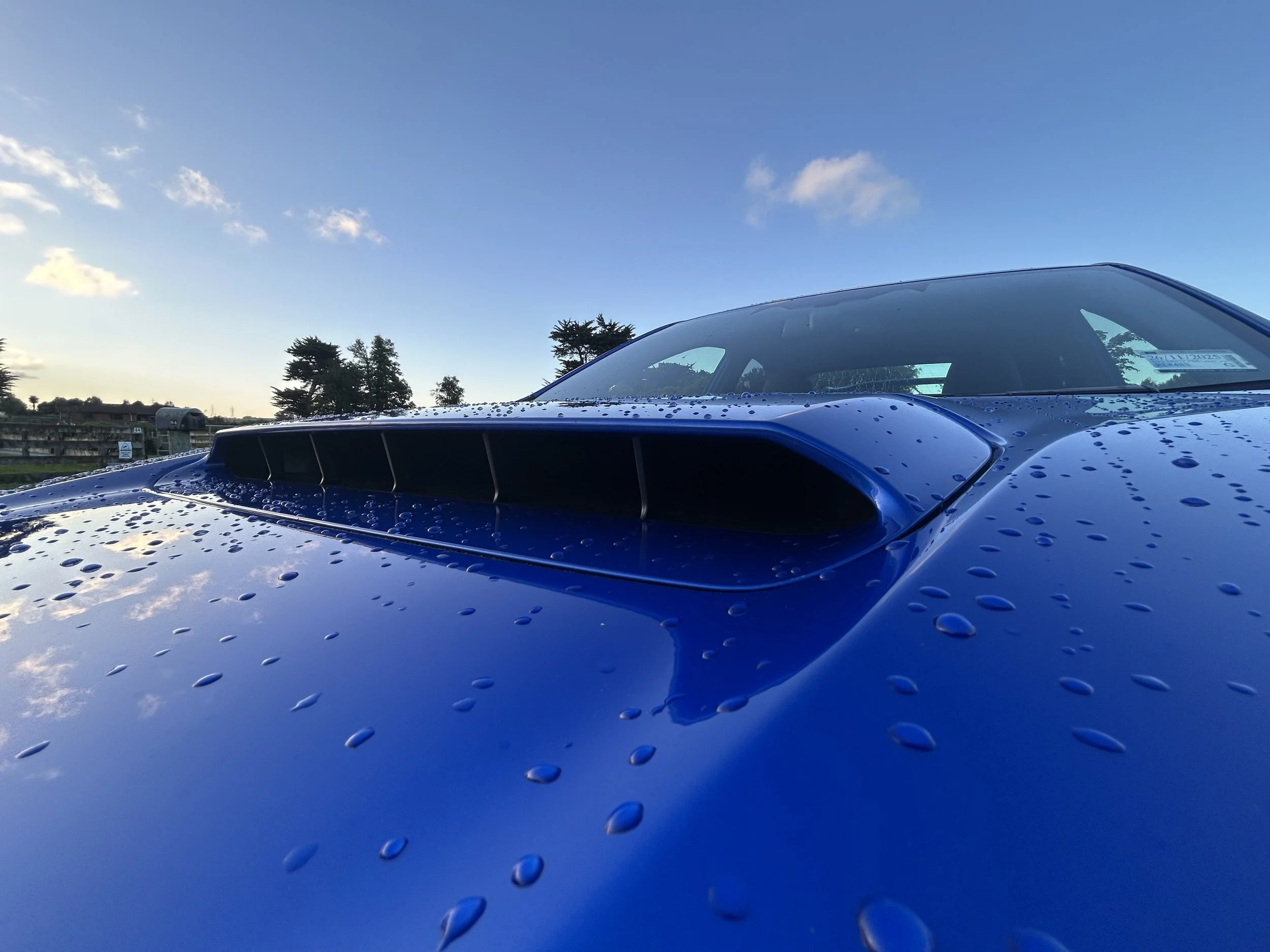

VW explained today that with large sedans like the ID.7, the body shape accounts for about 50 percent of the Cd value. The wheels and tyres influence about 30 percent, the underfloor 10 percent. Functional openings through which air flows to the radiators in the vehicle front end, for example, also account for 10 percent.

“When designing the ID.7, there was a greater focus on aerodynamics than for practically any other model,” said Volkswagen designer Daniel Scharfschwerdt.

“This can be seen in the low front end, the flowing transition into the bonnet, and the fast windscreen. The coupé-like roof form and the tapering rear end are also designed for ideal aerodynamic performance.”

VW maintains the prerequisite for optimal results is close collaboration between developers and designers.

Stephan Lansmann, project engineer responsible for ID.7 aerodynamics, adds to this.

“We strive for ideal solutions in an iterative process, which includes regular consultation between the Development and Design departments.

“There are many small steps here that pay off in the end. Numerous computer simulations for flow calculation are complemented by tests in a wind tunnel as part of this process.”

The ID.7 has an almost completely closed underbody. This is supplemented by wheel spoilers on the front wheels; these guide the air along the wheels under the vehicle with minimum turbulence.

Air curtains at the sides of the front bumper direct the air around the vehicles front end with minimum loss. The flared side sills prevent the air from flowing into the underbody area and shield the rear tyres from air flowing onto them. In addition, small spoilers and trim panels guide the flow of air on the underbody.

Such dedication to detail is an imperative, Lansmann says. On electric vehicles, the wheels make a greater contribution to good aerodynamics so “we therefore focused on them in particular.”

“When designing the wheel rims, the primary focus was on the aerodynamics, which we also had to match to the cooling requirements of the brakes.

“The resultant wheel rims are more closed and therefore have especially good aerodynamic properties.”

Flow simulations were also used when designing the tyre contours. This meant it was already possible to optimise variants with less good aerodynamic characteristics during the concept phase.

Other areas were also taken into account in the holistic aerodynamic development process. These include the functional openings at the front, for example, through which air flows to the radiators in the vehicle front end.

In the ID.7, the air flow is actively controlled by a radiator roller blind in order to reduce the drag. The electrically operated roller blind opens only when targeted cooling of the power units and battery is required. Aerodynamic efficiency at the rear is ensured by the ideally shaped tailgate and the design of the diffuser and side separation edges.

The progression from the computer to wind tunnel takes time; the

initial focus is on simulations, says Lansmann.

Several thousand processors are involved in calculating air flow values, also for numerous details like the flush-recessed door handles and the aerodynamically designed mirrors of the ID.7.

“We go into the wind tunnel only when the design is stable,” Lansmann says.

“That can take a good one and a half years from the start of development.”

The team used one-to-one clay models in the wind tunnel. The new findings are implemented on the model using a milling cutter with millimetre precision – for example, in the event of changes to the rear and to the separation edges. With the help of the prototype parts from the 3D printer, Stephan Lansmann’s team tested numerous variants – also for the aerodynamically shaped exterior mirrors, for example.

On the ID.7, this process allowed them to optimise the upper and lower mirror housing sections and mirror base to achieve a lower drag coefficient with outstanding aerodynamic properties.