Continental: Engine maker to the US vehicle industry

/Recalling the history of the enterprise that would power a diverse count of car and light trucks.

IF asked to compose a list of the 10 figures most responsible for the development of the American automobile industry, would your list include A.W. Tobin and Ross Judson?

Those men today may be less than an obscure footnote to automotive history. Yet the business they created was the very cornerstone for a staggering number of famous and forgotten manufacturers. It was also a foundational element in the development of the fledgling American aeronautical industry.

The story begins in 1901 when Judson, a gifted engineering student, had an opportunity to dismantle and examine a Mercedes L-head four-cylinder engine and noticed numerous flaws. The mechanical odyssey filled him with unshakeable conviction that he could resolve these issues and vastly improve that engine.

In 1902, almost immediately after graduation from the Armour Institute of Technology, Judson drafted a sales pitch that he presented to Tobin, his brother-in-law, an up-and-coming financier. His enthusiasm was infectious, and Judson soon had a partner in Tobin, a $US2000 investment of capital from this partner, a rented hayloft converted to a machine shop in Chicago, and a company incorporated as Autocar.

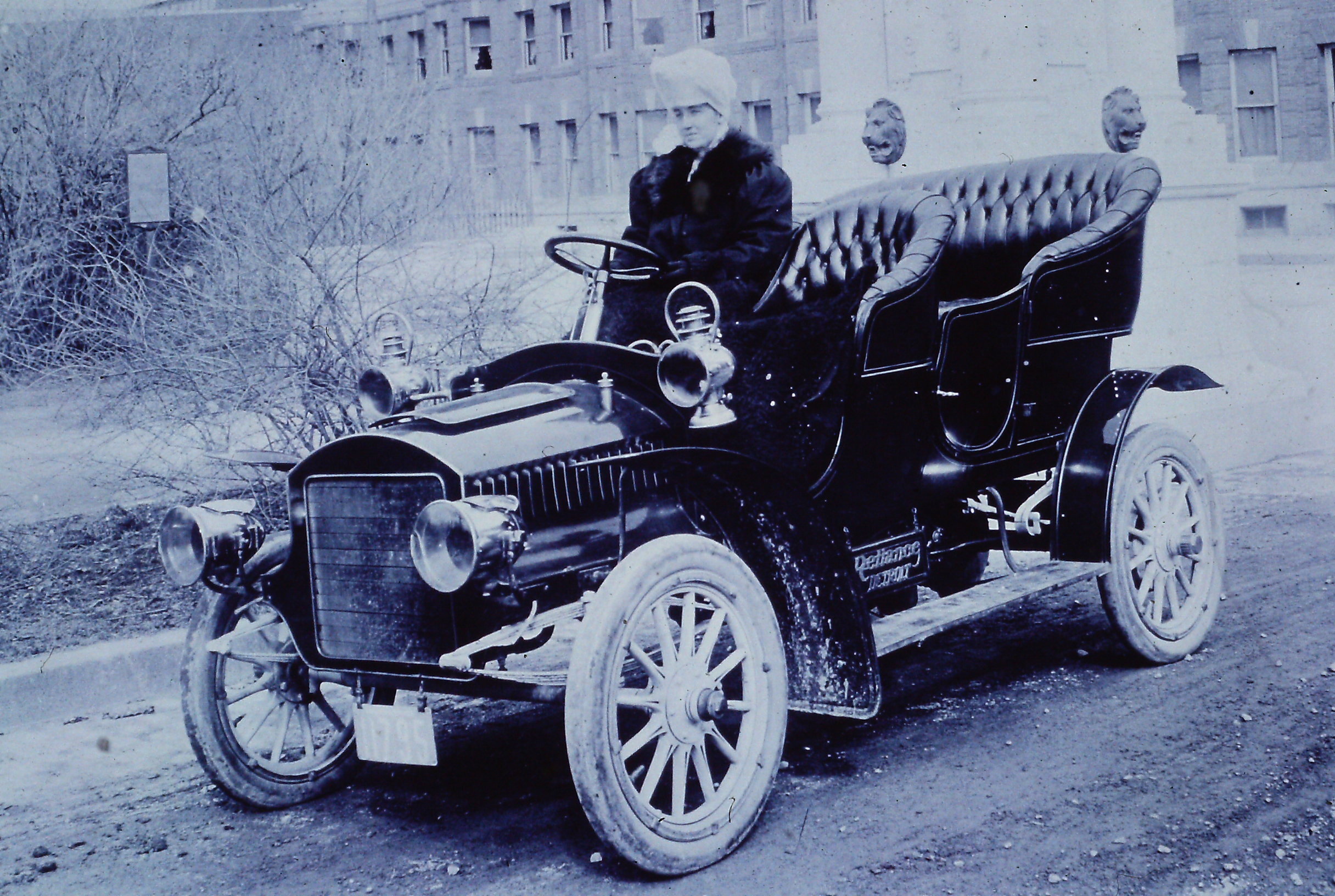

Judson’s first engine showcased by an eye-catching display debuted at the1903 Chicago Automobile Show. Judson and Tobin were possessed of unbridled confidence and had high expectations from this endeavor, but the inundation of orders must have left them stunned.

To fill these initial orders, the company hired 25 men and launched full-scale production along with expansion of the facilities. By 1904, Judson and Tobin found themselves in the enviable position of needing to find a location suitable for dramatic and immediate expansion.

Incentives provided by the city of Muskegon, Michigan, resulted in the relocation of Autocar operations and the construction of a state-of-the-art, 16,000-square-foot factory in 1905.

The following year, the company experienced equally dramatic changes and was already planning expansion as a result. As an example, Studebaker, just one of several customers, increased its order from 100 engines to 1000 in just six months. Production of stationary engines commenced and the number of employees increased from 25 to almost 600.

Then the fledgling company hit a major obstacle in the form of a lawsuit. Autocar, a manufacturer in Ardmore, Pennsylvania, had used the name since 1899 and was threatening to sue if the name of the Muskegon based company was not dropped. As a result, Tobin and Judson reorganised their company under the Continental name.

As an example of the men’s willingness to adapt to changing markets, in 1908 the company developed an aircraft engine production-and-development division. This would become a subsidiary, Continental Aircraft Engine, in 1929, with the 170hp A-70 radial engine as the foundation.

From its inception the company had turned a profit and expanded production each year. Then in 1910, with receipt of an order for 10,000 engines by a new manufacturing concern, Hudson, Continental launched an ambitious expansion programme that included addition to the Muskegon facility and construction of a second factory in Detroit. Two years later, Walter Frederick, a former engineer for the truck manufacturing concern Autocar, assumed Judson’s position as chief engineer.

Under his supervision, the company dramatically expanded the engineering department and launched the development of a line of engines specifically for catalog sales to automobile manufacturers, companies in need of stationary industrial engines, aircraft firms, and tractor manufacturers. And if a client requested engine specifications not listed in the catalog, staff engineers modified existing models accordingly.

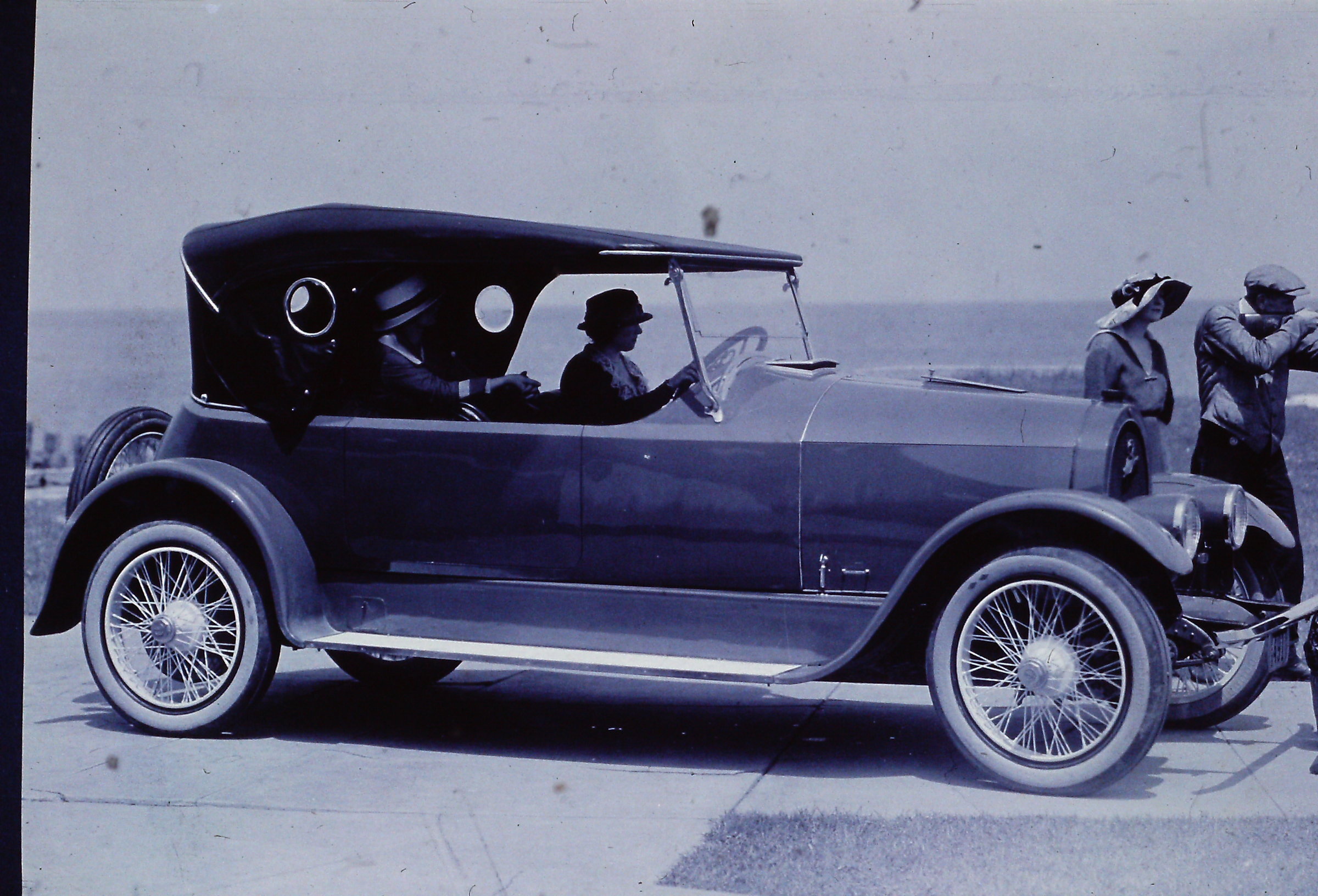

The next 20 years were golden for Continental. Automobiles manufactured by Apperson and Case, Crawford and Jordan, Ace and Vellie, Durant and Erskine, and more than two dozen other companies ran on Continental engines. Companies that manufactured trucks exclusively including Corbitt, Federal, Schacht, Selden, Sterling, and Reo used gasoline and diesel engines designed by Continental for industrial applications.

The 1920s was another pivotal period for the company. W.R. Angell, a member of the company’s board of directors, finalized an agreement with William Durant, the founder of General Motors and Chevrolet, to supply engines for his new lines of automobiles – Durant, Star, Flint and Ruby trucks for export.

The success of the company led to numerous purchase inquiries, and merger overtures. The most promising and thought-provoking merger negotiation was between Continental and three automobile manufacturers that utilized that company’s products – Peerless, Moon, and Jordan. In the midst of discussion Jordan was placed in receivership, Moon sales plummeted and Peerless suffered a series of dramatic setbacks. As a result, any plans for merger were abandoned.

The new decade and the dawning of the Great Depression began at Continental with Judson’s retirement and the rise of Angell to the presidency of the company. His expansion of the diesel truck, aircraft, stationary, and agricultural engine divisions of the company kept it afloat and even relatively profitable during the early days of the economic calamity.

However, his decision to initiate the launch of a Continental-manufactured automobile and the acquisition of a truck manufacturer nearly sank the company. The short-lived Continental Beacon, Flyer, and Ace were little more than new emblems placed on the equally unsuccessful De Vaux. The acquisition of Divco, a manufacturer of delivery and step vans, in 1932 proved another unwise, costly venture.

Norman De Vaux, a close friend of William Durant, had had several successes in the auto industry. He was instrumental in establishment of the California dealership network for Chevrolet and had worked with Colonel Elbert J. Hall in the establishment of Hall Scott Motor Company to produce aircraft, tractor, and bus engines. The De Vaux automobile endeavor was their second partnership.

Resultant of the worsening economic climate, poor sales, quality control issues and other problems, the De Vaux introduced in early 1931 was on the cusp of receivership by midsummer. To further complicate issues the company had an arrangement with Hayes Body Corporation to produce De Vaux bodies. And so, when the company was acquired by Continental, it was deeply in debt. Divco was not in much better shape. And so Continental was pushed to the brink of insolvency resultant of the acquisition. But the company survived.

The richly diverse legacy of independent thinking Ross Judson did not end with the Great Depression or the heady days of the post-war era. Continental engines powered the grandfather of the Jeep, the Bantam Reconnaissance and Command Car prototype, as well as the iconic Checker taxi through early 1964. Nor did it end with the cessation of engine manufacturing as Continental lived on into the late 20th century as Ryan Aeronautical and Teledyne Continental Motors.

Written by Jim Hinckley of jimhinckleysamerica.com