Saturn reached for the stars

/Automobile brands abandoned by their parent company are an integral part of the story of the American automobile industry.

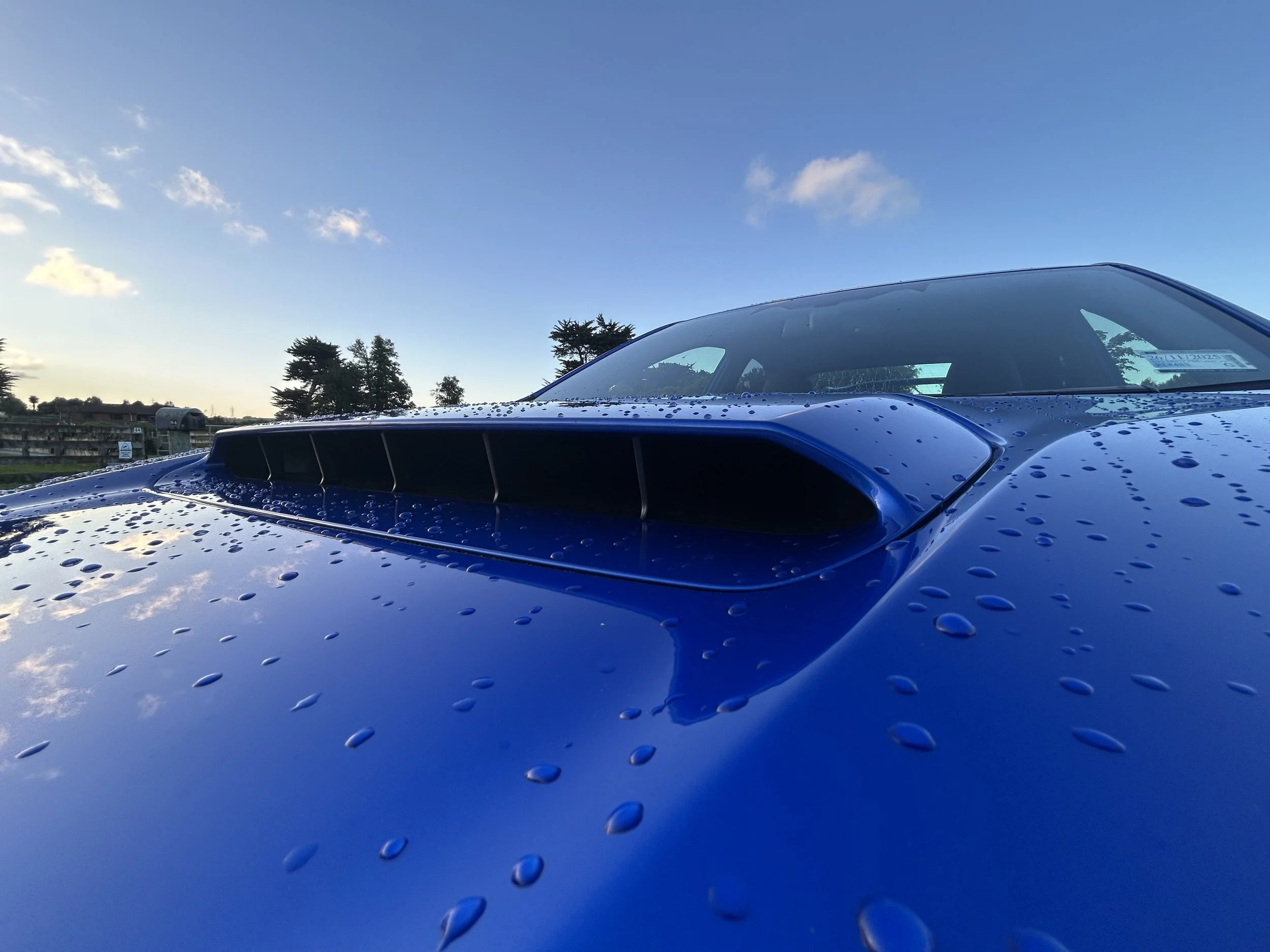

Even the Sky Roadster of 2008 was unable to draw enough consumer interest to sustain Saturn.

THE rise and fall of Saturn is a particularly interesting story - to a degree it mirrors the short-lived history of Ford’s Edsel.

It begins in 1982 General Motors when initiated an extensive study of the current and potential market for a small car built with the US domestic market in mind. This included styling considerations, projected trends, and the influence of Japanese and European automobile manufacturers on the American market.

The following year at a press conference about the project, then chairman Roger Smith announced plans to create a subcompact line of vehicles that would offer a direct challenge to imports.

The vehicles would be sold under the Saturn name, a reference to the rockets that had carried Americans to the Moon. True to his word, in near record time, the first Saturn prototype was readied for showing in 1984.

The project was placed on the fast track. The Saturn Corporation, also known as Saturn LLC, was established on January 7, 1985, as a GM subsidiary. Spring Hill, Tennessee, had been selected as the site for a state-of-the-art production and distribution facility. Then Joseph Sanchez died just three weeks after he was named Saturn's first president. In retrospect it was perceived to be an ill omen.

GM proved its commitment to the endeavor when ground was broken at Spring Hill and construction of a $1.9-billion manufacturing plant commenced in 1986. A few months later the Saturn logo was created and trademarked. Then in 1988, with great fanfare and extensive media coverage, the ribbon was cut for the revolutionary manufacturing facility at Spring Hill and 3,000 workers commenced to build the car of the future.

The innovative Z-body was developed entirely in-house at Saturn. Aside from the space frame design used on some Pontiacs during the 1980s it shared little with the rest of the General Motors model line. As the side panels did not carry a load, they were made of plastic polymer instead of metal. The dent and corrosion-resistant properties of the panels was incorporated into advertising campaigns.

Meanwhile GM had initiated an extensive program to establish a network of dedicated Saturn dealers and dealers that would add the new car to their line of offered General Motors products. In 1990 an extensive marketing campaign Saturn that focused on a brand-wide "no haggle" sales technique was launched to coincide with commencement of sales.

Production facilities, use of plastic body panels and visionary marketing campaigns were not only the innovative things about Saturn. The UAW (United Auto Workers) and GM initiated a series of meetings in 1983 to negotiate a labor agreement. In 1985 announcement was made that a labor accord for the Saturn operation had been completed. It included unprecedented terms including a twenty percent pay cut for workers at the Spring Hill factory in exchange for guaranteed profit-sharing and bonuses based on attainment of production and quality goals. Certain other rights pertaining to seniority, work rules, grievance procedures, were also modified.

The second cloud in the company’s bright future occurred in 1991 when an engine coolant problem necessitated the replacement of 1,836 Saturn’s. As with the Edsel, these issues tarnished the new cars reputation, made potential customers consider other available models, and created a public relations nightmare.

The Aura RX sedan was intended to achieve volume penetration. It didn’t.

This proved to be a minor setback. In early 1992 the company announced the sale of the 100,000th Saturn. Later that year Saturn was placed at the top of the list in the J.D. Power Customer Satisfaction index list. Then only a few months later the embryonic company was dealt another blow when it was announced that more than 300,000 Saturn’s were being recalled for the repair of an electrical issue.

Still Saturn reported its first profitable year in 1994. Again, much like what happened to Edsel, sales did not meet projections. As a result, there was a lay off at the Spring Hill production facility and production was curtailed. This was part of a company-wide reorganization that included the folding of Saturn into GM's Small Car Group.

But the company continued working on innovative programs and marketing campaigns to develop brand loyalty. One of the most novel of these initiatives was the Saturn Homecoming.

In the spring of 1994, the company invited 605,000 Saturn owners to Spring Hill for a celebration of the owners, the vehicles, and the people that built them. More than 38,000 people accepted the invitation. The only states not represented by owners were Wyoming, North Dakota, and Montana-the only states where Saturn had no dealers. L.B. Tseng, a Saturn dealer from Taipei, Taiwan, held a drawing among his customers and awarded 20 of them with a free trip to the homecoming, a promotion that cost him $50,000.

It was an unprecedented two-day event. There were bands, singers, magicians, and a firework display with "God Bless America" and "America the Beautiful" as background music. Blacksmiths gave demonstrations. Tattoo artists were available to provide an unforgettable souvenir. Angie Weaver and Curt Natter, two young Saturn dealership employees from Pennsylvania chose the occasion to get married before a chaplain of the United Auto Workers union. Saturn President Richard LeFauve said, “This is the first owner recall in the history of the auto industry."

The Saturn, like the Edsel, should have been a success. The S-Series produced until replacement by the Ion line in 2003 won numerous awards. Powered by a 1.9-liter four-cylinder single cam or dual cam engine paired with five-speed automatic or four-speed manual transmissions, the cars developed a cult like following. MotorWeek, Automobile Magazine, J.D. Power & Associates, and Motor Trend praised the car in feature articles. More than 2 million S-Series were produced.

Still, by 2000 Saturn had lost its identity. The midsize L-Series in sedan and station wagon body styles was produced at a GM plant in Delaware. They were based on the Opel Vectra.

In a valiant attempt to keep the brand alive, General Motors expanded the Saturn line. The Vue was introduced as a crossover in 2002. In 2005 the Relay minivan debuted. Two years later the stunning Sky roadster was offered.

But GM was in a dire financial condition. The company was losing billions of dollars and facing bankruptcy. When GM chairman Rick Wagoner testified before a Congressional banking committee, he explained that the company was in the process of streamlining by concentrating on its four core brands: Cadillac, Buick, GMC, and Chevrolet.

Saturn was doomed. Following GM’s bankruptcy and restructuring in 2009, the company attempted to sell Saturn. The only interested party was race car driver Roger Penske. The negotiations were stillborn when a deal to have Nissan-Renault supply cars to Saturn collapsed. With little ceremony GM quietly halted production of Saturn on October 1, 2009, and officially discontinued the line on October 31, 2010.

But just as with other orphans Saturn lives on. It still retains a staunch loyalty from owners. And a new generation of enthusiasts, many of whom were not yet born when the car debuted, have discovered the durable and sporty Saturn coupes. They have spawned a cottage industry of aftermarket and used parts.

Written by Jim Hinckley of jimhinckleysamerica.com