Gigafactory ‘perfect’ for Tiwai

/

An Auckland visionary believes Southland’s smelter site is a Musk-see.

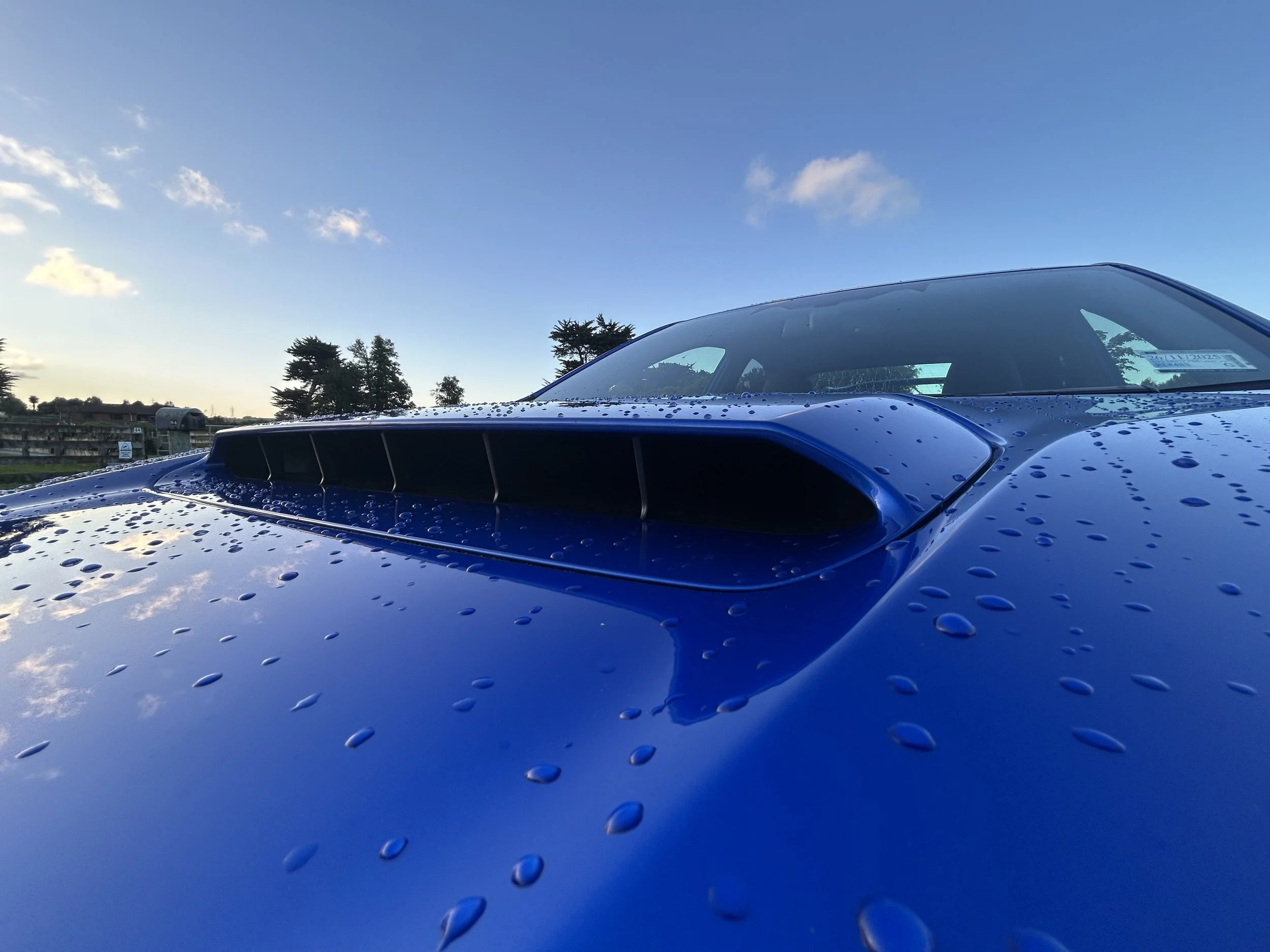

Tesla’s first gigafactory in Sparks, Utah.

AN electric vehicle infrastructure entrepreneur reckons his push to have the Tiwai Point smelter re-energised as a Tesla ‘gigafactory’ is worth taking to Government and the American car brand.

Nigel Broomhall says the response so far to a Facebook campaign launching immediately after the smelter’s closure was announced has fuelled an ambition initially proposed to spark discussion.

Experience in the electricity and electric vehicle sectors - ventures ChargeSmart and Invisible Urban Charging being undertaken with benefit of 18 years with Meridian Energy – has left Broomhill confident his concept will work.

“It’s the ideal spot for something new. The perfect location.”

A pile of responses to his pitch, not just directly to Facebook but also on a number of prominent EV owner sites has been largely supportive.

New Zealand is well-positioned for being a leader in Green energy creation, the Manapouri hydroelectric infrastructure that primarily feeds the smelter creates more than enough electricity for this new venture and the cost efficiencies are right, he argues.

Plus, while an alternate pitch for Tiwai – to turn it into plant producing hydrogen, another key fuel for future transport needs – also has merit, repurposing it as one of the giant battery-making facilities Tesla is creating around the world makes even better sense.

It’s big-thinking on a scale beyond anything imagined when the smelter and power scheme were created.

As the name suggests, a gigafactory is massive – the first, in Nevada, the United States, is the biggest building in the world at 1.76 million metres and with an annualised rate of around 20 GWh, claims the highest volume production of lithium ion batteries in the world. (See this tour of the factory produced by CNBC).

Since then Tesla has begun sister plants in Shanghai, China – supporting a factory making Tesla Model 3 cars for that country - and, more recently, in Germany.

On the outskirts of Berlin, the latter is also set to mirror the operation in Sparks, Utah, in making battery cells and battery packs in association with Panasonic, plus Tesla vehicle drivetrains, and the company’s two storage products, the Powerwall and Powerpack.

It’s this latest undertaking which has also provided the basis for a costings exercise that, Broomhill argues, shows why a NZ factory would be all the more beneficial for the international giant.

The core appeals are that an infrastructure exists and that it would deliver even better employment opportunity in a region set to be hit hard, with 1200 direct - and perhaps 1400 indirect – job losses when NZ Aluminium Smelters (NZAS) closes next August.

The ingredient of a power supply delivering 570 mega Watts and all the electricity transmission hardware, a commercial deep water port designed to manage raw materials and a high-trained manufacturing workforce would be appealing to Tesla, he feels, and very good for our economy.

“Even though the plant would be in Southland, having a technology leader like Tesla in NZ would have a huge ripple effect across the NZ technology industry. This would attract more technology players and grow our tech industry rapidly,” he argues.

The potential economic value of around $11 billion is estimated on published data for the German factory, which has been a $6.9 billion investment that has delivered 8000 jobs but is also based on Tesla having to wear electricity supply rates seven and a half times those Tiwai enjoys.

“The biggest opportunity we’ve got is price. Germany’s electricity price is horrendous, they are up around 35-37 cents per kilowatt hour whereas in comparison Tiwai is, according to recent articles, down around 5c (as a wholesale rate).”

Pundits have already identified that closing Tiwai will free up a swathe of hydro electricity and potentially lower national prices, but getting what the smelter takes now – and that’s 13 percent of the national grid’s capacity – to the rest of NZ won’t be cheap. It demands a $100 million upgrade (the Clutha Upper Waitaki Lines project), cited to take at least three more years.

Broomhall’s approach really negates the need for any of that, though he suggests Tesla’s operation would likely be more efficient and perhaps only need no more than half the power going into Tiwai now.

In saying that, he concedes there’s one aspect of the Utah facility that would be challenging to emulate in Southland. The Sparks plant is designed to be a zero-energy facility, consuming no fossil fuels and using electric sources to power the back-up emergency generators. So the entirety of the roof is covered in a solar array and any power not consumed during the day is stored in powerpacks for use when needed.

Nigel Broomhall says his Tiwai Point idea might be a long shot, but he’s used to “throwing things at the wall and seeing what sticks.”

Broomhall says that probably wouldn’t be achievable at Tiwai Point. “The solar gain is not huge down there but you wouldn’t need to do it because they have that massive direct feed from Manapouri. So there’s no need for renewables.”

Given a gigafactory’s output is critical to vehicle production, why not push for a Tesla car plant?

As an ardent EV fan, he’d love to see the make’s vehicles made here, but says that probably would be a leap too far.

“If they wanted to do cars, that would be fantastic, as it requires a lot more workers.”

Getting a gigafactory going would depend on how quickly NZAS could scale down and clean up their site, but regardless of that it would be expedient to at least gauge Tesla’s interest.

Tesla’s gigafactory plan is surrounded in conjecture, but in 2018 Elon Musk talked about the need for 10 to 20 such facilities for Tesla to achieve planned products and volume. He also said then that the world would need 100 gigafactories to make enough electric cars and batteries for global demand.

The next step? “If the Facebook page we've created gets to 10,000-plus likes, we'll build a business-funded team and pitch Tesla. We'll co-ordinate across the electricity industry, local and central Government.”

Tesla sees need for numerous gigafactories to feed to emergent demand for electric cars.