Fly-through captures Gigafactory buzz

/A look inside Elon Musk’s Berlin plant comes as analysts wonder if Shanghai factory is under the pump.

HERE’S opportunity to take a flying visit to Tesla’s just-commissioned Berlin Gigafactory.

To give an idea of what goes on within its especially vast confines, the make has released a drone-shot video that takes the viewer all over the shop, including into places that humans cannot venture for safety’s sake. The pressing area being one.

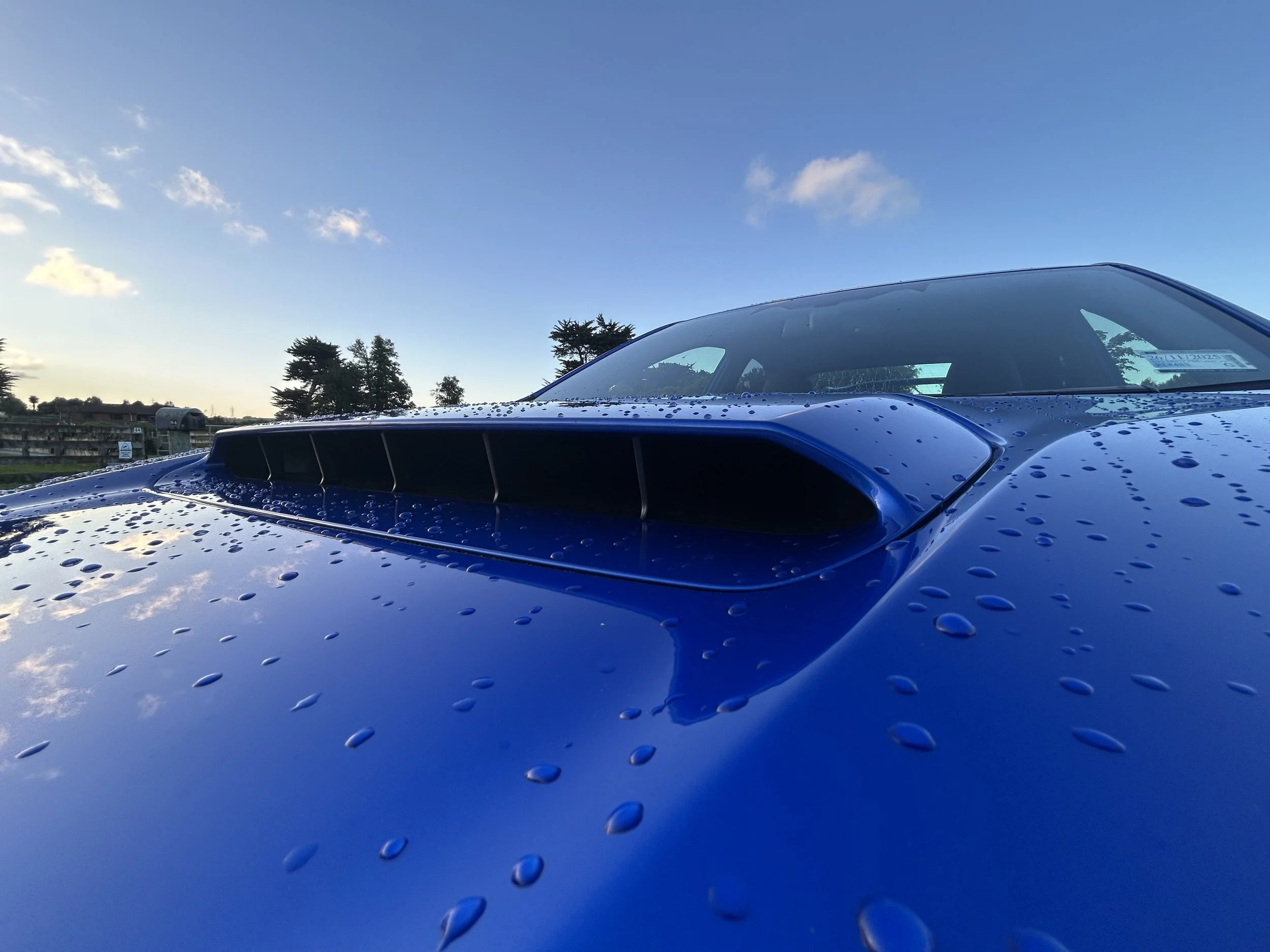

The video opens with footage of parked Tesla vehicles, then the drone swoops through a door to the factory. The camera squeezes through tight assembly lines, expertly waiting for robotic arms to move out of the way before continuing. Viewers see the entire assembly process and footage of finished cars before the drone streaks out of the building.

The plant only opened on March 22 so, conceivably, and is still coming up to speed.

The fourth Gigafactory and the first in Europe, Berlin coming online could be beneficial for a sister plant in Shanghai, China, that’s the primary sourcing point for NZ-bound Teslas – which these days are just one kind of car, the Model 3.

That’s according to the Financial Times, which says Tesla Shanghai needs some much needed breathing room to meet China’s growing appetite for electric vehicles.

The paper’s online edition says the Berlin plant needs to increase production quickly to help Tesla capture massive — but possibly fleeting — demand from China, where the US company is unable to keep up with orders.

China has become Tesla’s key market since the Shanghai Gigafactory opened. Company revenue in the country has doubled for two consecutive years, hitting $US13.8 billion in 2021, according to filings.

China has also become the backbone of Tesla’s manufacturing for global customers amid overall supply chain constraints. Due to pandemic lockdowns, a global chip crunch and labour shortages, Tesla’s Shanghai Gigafactory ended up being tasked with manufacturing more than half of all Tesla vehicles in 2021.

But bearing the brunt of Tesla’s manufacturing needs has come at a cost, the FT says. More than half the Tesla vehicles produced in China in the past two months were for export, forcing Chinese Tesla buyers into long wait times for delivery.

It is a less than ideal situation for the EV maker, as both local and foreign players are quickly gaining ground in the growing Chinese market.