Bump thumps to ballistic blast

/A recently-opened test ground with every latest ingredient is making massive difference to Mahindra’s vehicle development programme. It was our playground a day.

LINKING two straights long enough for vehicles to hit 200 kilometres per hour are banked parabolic curves, each precisely at 43.7 degrees - just right for ‘neutral’ hands-off testing if you’re brave enough. Not me.

Mahindra’s184 hectare MSPT test facility at Tamil Nadu is a proving ground that has everything save an extreme cold testing chamber. Not easy to have here when the day time temperature never drops below 24 C. On our day, it was a gruelling 39.

In a location where the temperature reached 39 degrees on day of our visit, and never drops below 24, that’s simply an impossibility. For now, any way.

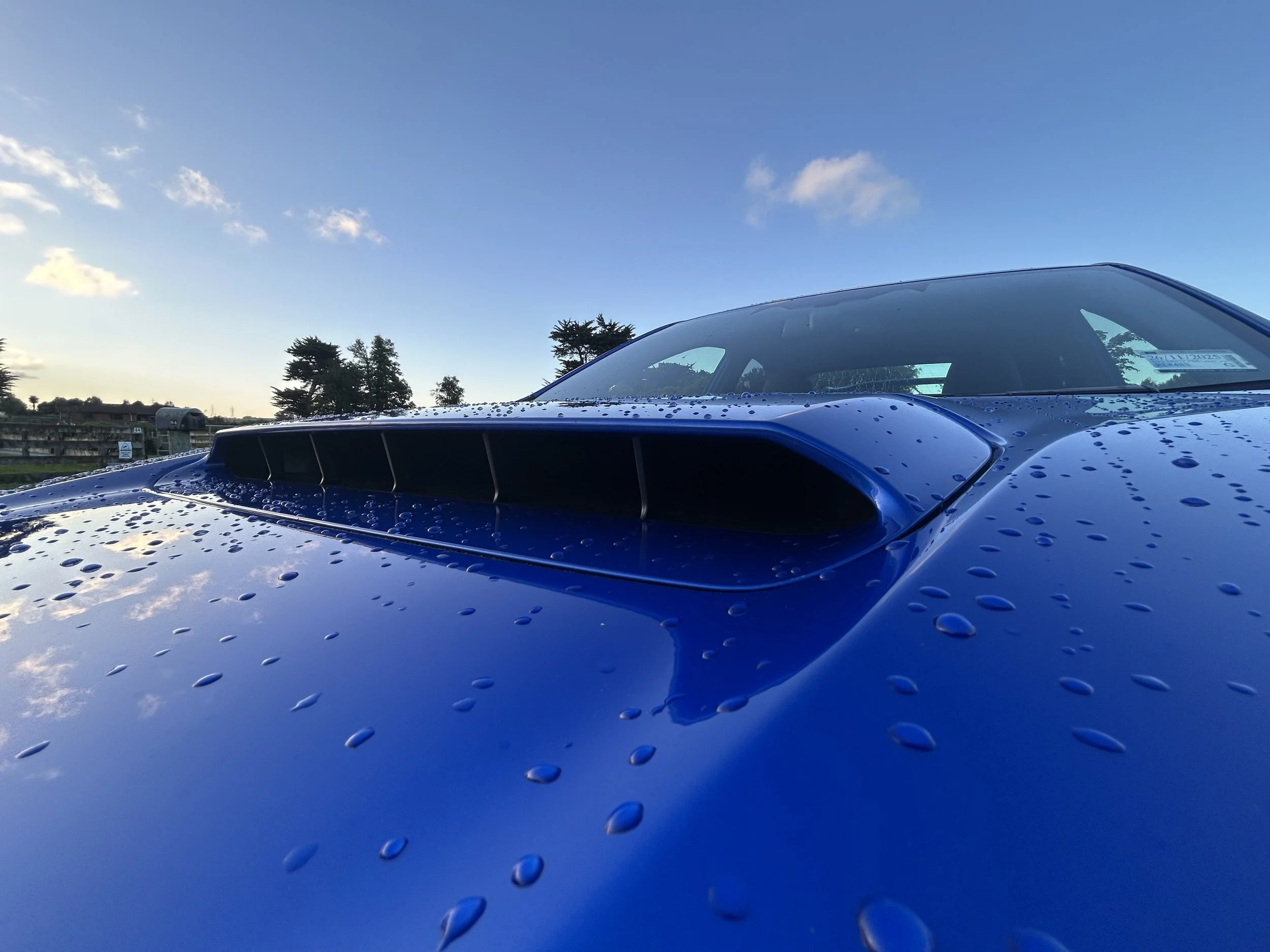

This is a hugely impressive facility. Kilometres of roads, representing all kinds of driving conditions and road surfaces including various grades of asphalt, potholes, manhole covers, corrugations, inclines and wet surfaces.

Then there’s the centrepiece. The four-kilometre, four-lane high-speed test track, with banking-connected 1100-metre straights lends opportunity for this make to assess their sports utilities at double the national highway speed.

On our day, the brand’s mainstay sports utilities, the XUV700 that has been in NZ since February and the Scorpio about to come into the market, and subject to first drive evaluation (see the ‘first drive’ section), took the test.

During our pre-run briefing, we were ‘invited’ to pin back to 160kmh and the cars were set to show a speed warning at that pace.

During the driving exercises, the company representatives riding shotgun were relaxed about the reins being loosened. We could go as fast as we dared. But we weren’t officially allowed onto lane four, the highest part of the curve. Lane three at the ton was enlivening.

The one ‘Mahindra’ car that could conceivably hit absolute pace here has yet to visit. It’s the 1416kW/2340Nm hyper car hand-made in Cambiano, Italy.

Of the 150 Battistas built, two are in Indian hands; in the keeping of a billionaire who has never regretted buying Pininfarina. He purportedly has one in his home garage, the other in Europe.

The type has already established a cool street - well, test track - cred. Back in February the car established the fastest speed ever set by any road vehicle on Indian soil.

That 358.03 kilometres per hour effort, plus the establishment of new production car world records for 0-300kmh (10.49 seconds) and quarter-mile acceleration (8.55 seconds), occurred at another location, NATRAX near Hydrabad. But there’s sense the custodians at MSPT hope that one day overall brand boss Anand Mahindra will fang his one around their place.

As is, other electrics are seemingly starting to come to life here, because they’ve become more important to this maker.

India has committed to becoming a global centre of electric vehicle development and production. Mahindra is utterly committed to this crusade.

It has partnerships with Volkswagen (to use the MEB platform) and a battery provider in China to develop up to five electric SUVs coming out within the next five years.

It is also set to covert existing internal combustion cars into battery-pure choices. The for now diesel Scorpio and petrol XUV700 seem set to live on in that world.

The rework starts at Mahindra Research Valley (MRV); handily just an hour down a road continually congested by colourful traffic. While motorbikes, cars, buses so packed patrons will be seen hanging onto the sides and trucks are everywhere, Indians seem happy to use any kind of motorised vehicle for transport. Those that cannot, simply walk - and not on the roadsides - and, of course, there are also dogs and wandering cows. That the selection of crash testing items at MPsT includes a herd of life-sized horned bovine dummies relates to the size of the problem they pose.

MSPT is touted as a 4x4 ‘centre of excellence.’ We found plenty of adventurous terrain. More than 25 obstacles to ensure Mahindra SUVs are capable off-road as well as on road.

Up and down hills (slopes 7, 11, 18, and 35 degree), woods, riverbeds (0.9m and 1.2m deep), mud, slush, sand, rock beds, a sea saw, a rickety wooden bridge over river pass, hard and soft articulation, wood logs, railway sleepers and a dead drop.

Elsewhere there is a circular dynamic platform that spans 250 metres in diameter, meant for vehicle dynamics development and evaluation.

There’s a braking pad with six different surfaces. Dry and wet tracks to test braking, ABS, stability and traction controls. The wet runs are across tiles, highly polished to lessen grip which disappears when they are deluged with 12000 litres of water per minute, to simulate ice. The sudden flood disturbed from the drains a resident rat that adeptly dodged our vehicles.

A general ‘highway durability’ track and a ‘ simulated city’ track are to test public road durability.

An accelerated test track has all imaginable bad road surfaces including potholes, undulations, Belgian pavement, cobblestone and rumblers.

Various kinds of wash board and speed breakers are factored into it. Mahindra folk were surprised they didn’t have anything quite replicating our coarse chip, the bane of suspension and tyre specialists the world over.

India’s climate is tough; Monsoon conditions are legendarily unpredictable with storms and floods. MSPT can simulate rain, water wading and water splash. India has deserts. The test ground has a chamber in which a dust storm can be simulated.

And to find cold? At the moment this sports utility specialist heads either north into the Himalayas or travels way down south … all the way to the Pisa Range, between Cardona and Wanaka.

An engineer hosting our visit was heading to the Southern Hemisphere Proving Ground that very night, to continue development work of the new generation of Mahindra’s most adept wilderness product, the Thar.

MSPT houses a Full Vehicle corrosion test facility with humidity chamber.

Exclusive prototype workshops, health centre and an administration tower housing more than 200 engineers. plus, of course, it has its own fuel station.

They’re also now building an advanced crash-testing facility; India’s domestic crash testing standard, G NCAP, has done much to improve domestic vehicle integrities, but its not as as stringent as the European and Australasian NCAP schedules we prioritise. The new centre is integral to brand intent to reach fully international standard.

Everything about MSPT reminds that designing and engineering cars is a highly complex business. Designing and engineering car testing grounds is as well.

IDIADA (Institut d'Investigació Aplicada de l'Automòbil - Institute for Applied Automotive Research) in Spain was the architect Mahindra turned to. The fine-tuning was all local.

The writer attended this event as a guest of the distributor, with travel, accommodation, meals and a small gift provided.