Seen to be green - Farizon voices eco message

/China’s electric commercial kingpin says good environmental intention must begin with sustainability effort on the production line.

CHINA’S dominance into the electric vehicle sector market might well be hailed as good news for climate action.

But comment from one involver now establishing in New Zealand enforces Green intention has to start in production, not on the road, if it is to truly resonate.

China's manufacturing prowess has been a driving force behind the rapid adoption of affordable EVs globally, accounting for 50 percent of global EV production.

In respect to expertise in battery production and innovation, China is well placed to accelerate improvements in EV technology.

But until now involvers have never seemed keen to voice any particular Green credential and overseas’ reports say the environmental implications of China’s dominance in the EV sphere remain … complicated.

As much as the shift away from internal combustion power plants there has begun to deliver positive impact on the major air cleanliness issue, the transfer to ‘new energy vehicles’ has not been without climate impact.

One emergent concern that, if not managed sustainably, China’s control over critical battery materials could lead to environmental damage in all manner of forms, from intensive mining practices, to water and air pollution.

Also, as EVs take over, the surge in electricity demand may lead to increased coal consumption in regions heavily dependent on coal-fired power plants.

Production of the vehicles themselves is also not without issue: battery manufacturing in particular generates higher emissions in comparison to conventional vehicles, creating a “carbon debt” that requires time to offset.

Given this, it’s interesting perhaps to see new market entrant Farizon, which only founded in 2016, has stepped up to front-foot an eco-consciousness message.

The primary commercial marque within the Geely enterprise is in infancy here, but long-term intent should not be under-estimated and perhaps explanation of the care it appears to be taking in producing vehicles might assist in raising its profile..

Battery-pure passenger vehicles are still battling back into the consumer mindset, and the commercial sector has proven resistant - other aspirants, notably LDV and Ford, have not found it at all easy to penetrate those diesel-dominated scenes.

But when Giltrap Group announced its new China-focused NordEast division in late August, it ensured the first Farizon products here - a van called the SV and a dual cab utility, the Riddara RD6 - got their share of the spotlight.

Last week Giltraps announced a key internal appointment to head the brand; Kevin Richards has until now run Volkswagen Commercials.

A restructure within the German marque’s national representation brings the car and commercial activities together, so Richards has moved on to lift Farizon’s profile.

He has extensive experience with the classes the Chinese make delivers and knows electrics well, being the architect of the prolonged pitch to get the ID.Buzz into local circulation.

Persuading potential Buzz buyers to cope with a high price surely won’t be a bugbear with Farizon.

As is always the case, the Chinese product manages to deliver coherent price advantage over cited rivals from makes outside of its homeland.

The SV van is intended to show in 170kW front-drive forms in 67kWh and 83kWh lithium iron phosphate battery sizes, all with ranges above 300 kilometres, and in several body shapes, sized between five and six metres, from $74,990 to $89,990.

Riddara RD6 is delivering $69,990 flagship type that has a 73kWh battery of the same chemistry as the vans, feeding dual motors developing 315kW/595Nm combined.

It promises up to 360 kilometres’ range when measured to WLTP, delivers a 1030kg payload, three tonnes’ towing and will hit 0-100kmh in 4.5 seconds.

NordEast is considering expanding Farizon beyond vans, with interest in trialling the make’s H9e light electric truck here, but small electric wagon with a truncated utility deck seems unlikely.

An interesting aspect to the Farizon pitch, yet to be exploited by the NZ distributors was internationally voiced this week.

Having become China’s first commercial vehicle brand to offer a full range of new energy product, Farizon has further expressed commitment to becoming a comprehensive intelligent and green transportation technology service provider. That does not just restrict to electric but also development of powertrains reliant on methanol/hydrogen blend.

Beyond that, it is expressing environmental credential by highlighting the use of recycled and recyclable materials in its product, with the SV van being used as an example.

In its construction, Farizon says, the SV uses 10 percent recycled materials, while 85 percent of its materials can be recycled at the end of its life, and 95 percent are recoverable.

Out on the road, the use of high-strength steel and hybrid aluminium-steel materials in the chassis and body, along with the innovative drive-by-wire platform, helps reduce weight by eight percent, which provides gains in energy conservation and operational efficiency.

In addition to these significant advances, a large part of Farizon’s environmental focus has been spent on low carbon manufacturing.

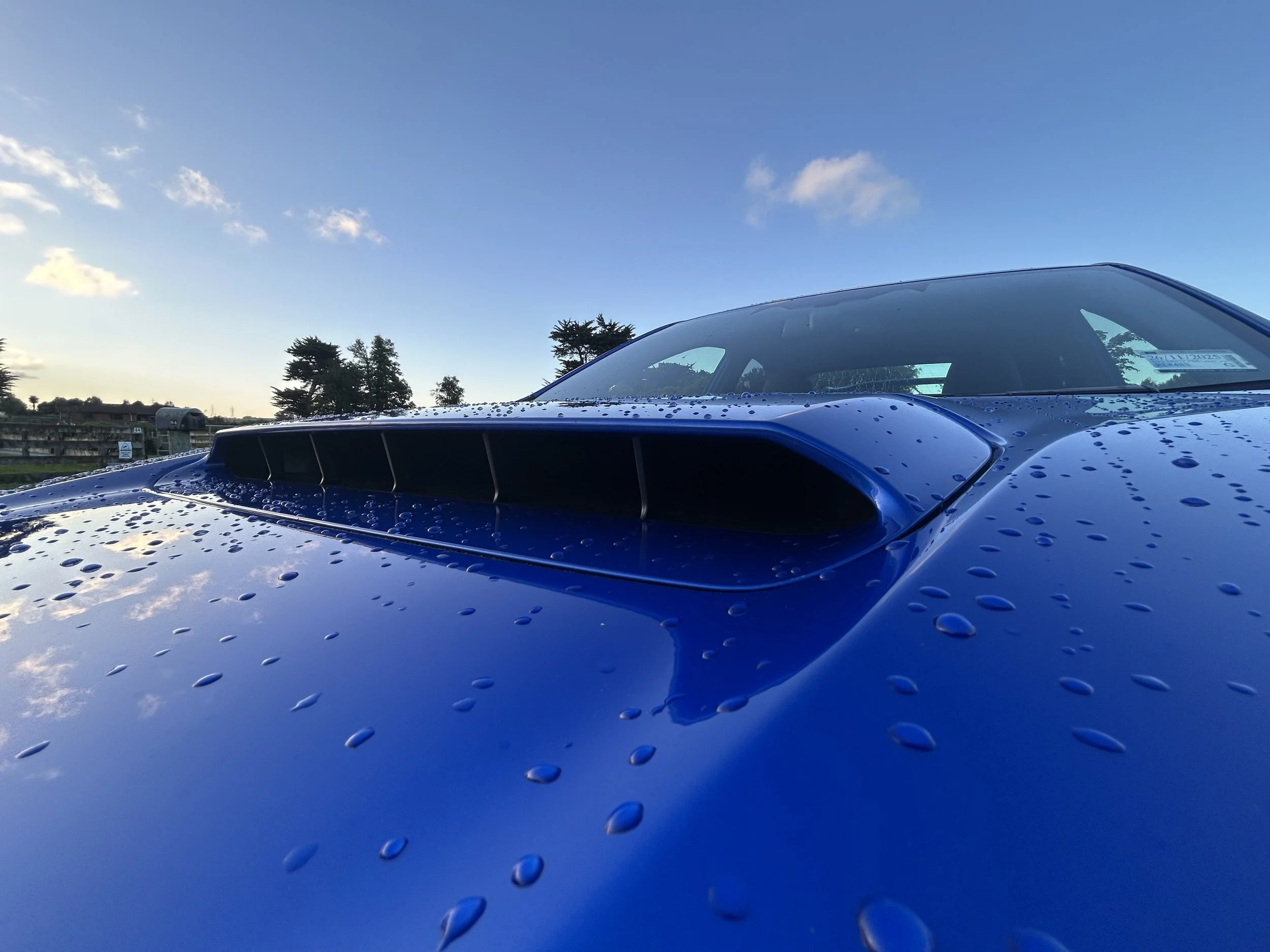

Located in the Xiangtan Economic Development Zone in the Hunan province, Farizon’s flagship manufacturing facility (above) has been created to be a global benchmark for carbon-neutral commercial vehicle production.

Designed from inception as a zero-carbon factory, the base plans to operate on 100 percent renewable energy, primarily from solar and wind, with on-site generation capacity exceeding 40 percent of total consumption.

Its closed-loop water recycling system reduces freshwater dependency by 75 percent, while AI-optimised logistics networks cut ancillary emissions by 30 percent.

Farizon says its manufacturing ethos prioritises cradle-to-cradle principles. More than 95 percent of production waste is recycled, including metal scraps, plastics, and battery materials.

Paint shops utilise water-based coatings with near-zero volatile organic compound (VOC) emissions, and welding lines deploy laser-brazing to eliminate lead-based solder.

Interior components feature ocean-recycled plastics and certified organic fabrics, reducing virgin resource use by 50 percent. SV production also leverages a digital twin system to simulate energy use, ensuring each van’s carbon footprint is tracked and minimised.

Sustainability extends beyond the facility itself. The plant enforces a Green Partner Certification for all Tier One suppliers, mandating ISO 14001 compliance and carbon disclosure. More than 60 percent of components are sourced from within a 500km radius, and electric inbound logistics further reduce emissions. Community initiatives include a battery regeneration hub that refurbishes used EV packs for solar farms, and a training centre that upskills workers in circular-economy manufacturing techniques.

Farizon’s chef executive, Cook Xue, expresses that “environmental considerations are rightly key for both large fleet operators and individual tradespeople when deciding which all-electric van is right for them.

“We’ve worked hard from the outset to ensure the new Farizon SV van features sustainability at its core, whether that’s in sourcing components from a localised supply chain, implementing low carbon manufacturing techniques, or ensuring drivers benefit from exceptional efficiency.

We have more work to do, certainly, but we are proud of the industry-leading advances we have made.”

Farizon has doubled its Chinese market share for three consecutive years and this year reached the milestone of 300,000 unit sales, becoming the first new energy commercial vehicle brand in China to achieve this goal.