Electric more dominant in Toyota’s future

/Shareholder discontent quelled; swathe of developments outlined.

KIWI consideration of New Zealand of Toyota as a highly-trusted brand comes as the giant make has just withstood shareholder rift in Japan.

Toyota New Zealand has outlined a good news story - having moved up three places to fourth in the 2023 Kantar Corporate Reputation Index, a national survey in its eighth year.

The local trumpet blow came on June 15, immediately after a tough day for Toyota Japan.

The brand’s annual general meeting saw it also share plenty of positives, with commitment to a swathe of new technology to “support its transformation into a mobility company”, which includes new EV battery types and vehicle construction methods.

It’s working on a series of long range batteries that will more than double the range of its current model (under the Lexus brand, as well as the parent’s) by 2026, and provide around 1400 kilometres’ range by 2030.

However, the AGM was also an event at which storm clouds threatened.

Shareholders were split on how well it is doing on fighting climate change right now and the speed of progress it has previously shown towards a fully electric model range.

The Associated Press news agency says the latter proposal was initiated by AkademikerPension, a $32 billion Danish investment fund.

It accused Toyota Motor of lobbying to weaken efforts by governments around the world to phase out the internal combustion engine; a position rejected by the majority of the 3800 shareholders at the meeting in Toyota city, central Japan.

Toyota’s technology proposals seem to counter that ideal. They cover a vast subject matter, from new vehicles and big improvements to its full electric and hydrogen fuel cell programmes to better manufacturing processes and determination to make some strategies regionally-focussed.

It aims to produce more efficient, faster-charging versions of current batteries to improve electric vehicle driving range - with claim it will within a few years have a car capable of clocking 1000km before need to recharge - and cost, and, within the decade, mass produce game-changing solid-state batteries after saying it had overcome a technical hurdle.

All of this could deliver positive potential for Toyota NZ, though it has yet to comment.

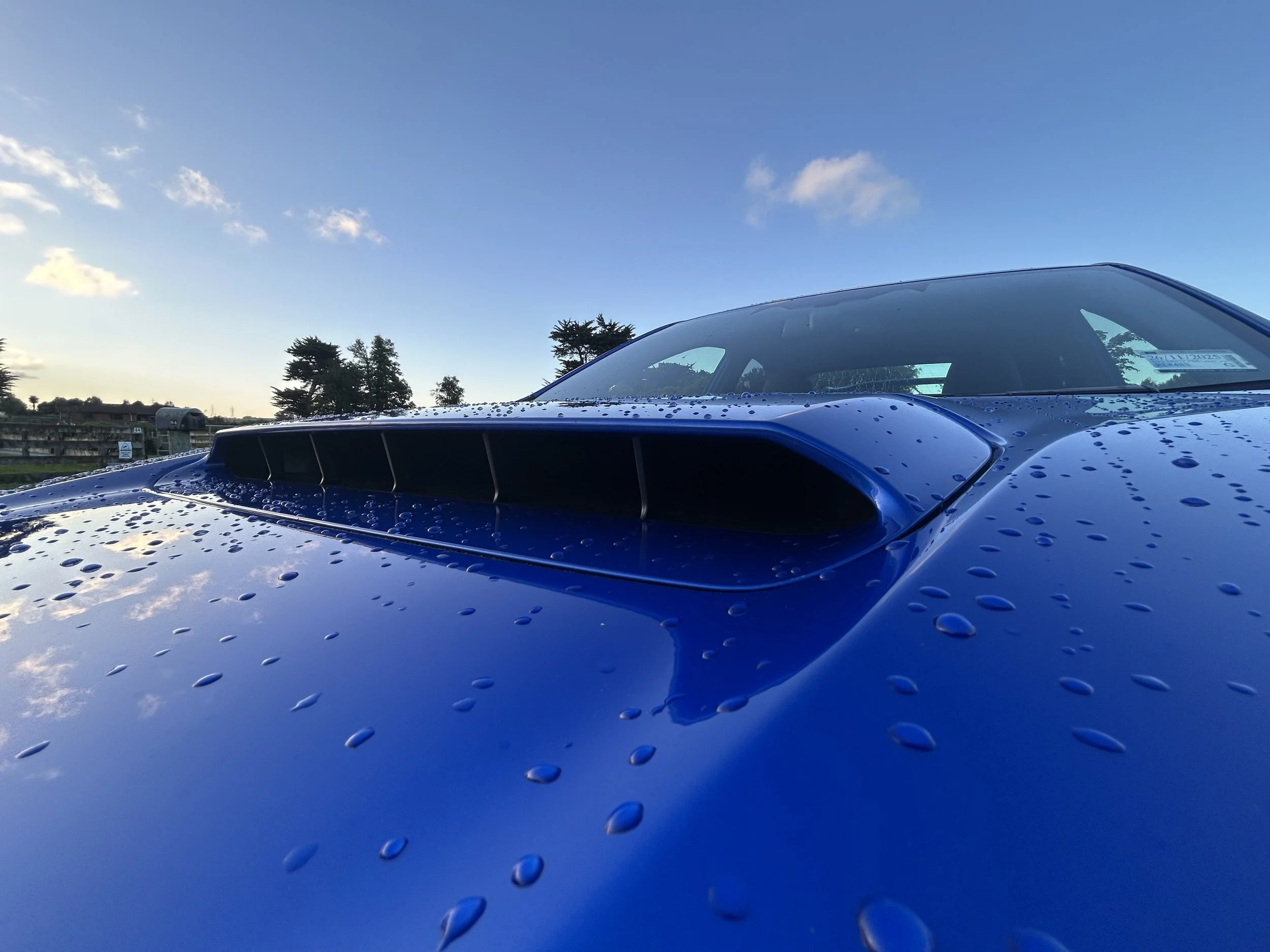

Delays with the bZ4X (above) mean the national operation still lacks a fully electric car - though the upmarket Lexus sub-brand has two on sale here.

The most recent Lexus, called RZ, is spun from the bZ4X, which Toyota and Subaru co-developed. The latter’s being the Solterra, now signalled as a December arrival. RS has the same basic technology, but with a Lexus look.

TNZ is the only brand to have publicly committed to Government’s emissions’ reduction programme yet benefit has been short-term.

It has been jolted by Clean Car revision, enacting on July 1, that curtails current rebates on almost all its trademark petrol-electric hybrids. Popular types that previously earned their buyers a cheque are now subject to penalty. TNZ has stuck to its hybrid commitment, saying last week that from September its Signature Class used import programme will restrict to these alone.

The latest strategy announced in Japan builds on earlier expressed commitments.

Chief technology officer Hiroki Nakajima talked about specific and diverse technology, including concepts currently under development, which would will help Toyota “achieve the vision and policies it has communicated”.

He and Takero Kato, president of the company’s new Battery Electric Vehicle production centre, and Mitsumasa Yamagata, president of the company’s hydrogen factory launching next month, provided more details of their respective strategies for the battery EV and hydrogen businesses.

Toyota had earlier said its three focuses were electrification, intelligence and diversification.

In electrification, it would take a “multi-pathway approach,” including the introduction of optimal powertrains for each region.

In intelligence, in addition to vehicles and services, it would also promote initiatives to expand its connection with society.

Localisation will be boosted, Toyota saying: “As the needs of our customers in each region will differ further in the future, we will accelerate ‘development near our customers’ at our R&D bases around the world.”

In response to criticism it is lagging in EV development, Kato said Toyota was set to roll out next generation BEVs globally and a full line-up will launch in 2026.

“By 2030, 1.7m of 3.5m units overall will be provided by the BEV Factory.

“These next generation BEVs will adopt new batteries, with which we are determined to become a world leader in energy consumption.” Kato said that technology would “achieve a vehicle cruising range of 1000km (600 miles).

In respect to battery technology, liquid lithium-ion batteries, which are currently the mainstream, would gain performance through improvement of energy density in square batteries, an area where Toyota has long expertise.

By adopting the bipolar structure developed for hybrid electric vehicles (HEVs) for BEVs, the automaker would expand its range and offer options from low cost to batteries “designed for higher performance”.

“Highly anticipated” all solid state batteries were “entering the practical application phase for use in BEVs. Toyota’s full line-up of competitive batteries will support the future evolution of the company’s BEVs”.

The performance version of the next generation battery is being developed with Prime Planet Energy and Solutions Corporation; the ‘popular’ and high performance versions and the solid state BEV battery are being developed with Toyota Industries.

The next generation BEV, to be introduced in 2026, would have a cruising range of 1000km and Toyota was developing a square battery with a focus on performance for installation in such cars.

While the battery’s energy density would be increased, cruising range would be increased through higher efficiency in areas such as aerodynamics and weight reduction.

Costs would be reduced 20 percent compared to the bZ4X signed off for sale in New Zealand - but now not expected until 2024, almost 18 months behind original schedule - and quick charging (10-80 percent) will take 20 minutes or less.

Toyota says it is developing low-cost batteries to encourage spread and expansion of BEVs. The bipolar structure battery, which has been used in the (Japan domestic market) Aqua and Crown hybrid vehicles, was now being applied to BEVs. This uses inexpensive lithium iron phosphate (LFP) and was expected in BEVs in 2026-2027.

Toyota was aiming for a 20 percent cruising range boost, 40 percent cost reduction and quick 10-80 percent recharging in under 30 minutes compared to the bZ4X. It was considering installing the battery in BEVs in the popular market price range.

A high performance battery combining bipolar structure with high nickel cathode would be put to practical use in 2027-2028. It would achieve greater performance than the ‘performance’ version of the square battery with a claimed 10 percent increase in cruising range, 10 percent cost reduction and quick charge time of 20 minutes.

“Having discovered a technological breakthrough that overcomes the longstanding challenge of battery durability”, Toyota was reviewing introduction of all solid state batteries for conventional HEVs and accelerating development as a battery for BEVs, “for which expectations are rising”.

On the manufacturing side, is planning a radical redesign, having vehicles drive along the production line instead of being carried by conveyor. It will also employ, a die-casting process already used by Tesla in some plants, that eliminates welding.

Yamagata, the hydrogen factory president-designate said hydrogen markets in Europe, China and North America would be the world’s largest by 2030 and the fuel cell market was expected to expand rapidly towards that point, reaching $11.7 billion a year.

He said: “We are promoting external sales of fuel cells, using the Mirai’s hydrogen units; we have received offers for 100,000 unit sales by 2030, most of them for commercial vehicles.”

The Hydrogen Factory would promote localisation of research and development and production in countries within the major world markets and boost establishing local bases, mainly in Europe and China. Alliances with suppliers would be extended.

Toyota would work on the “innovative evolution of competitive next generation FC technologies,” such as cell technology and FC systems.

“The next generation system will achieve 37 percent cost reduction through technological progress, volume efficiency and localisation.

“In collaboration with partners, if we receive and offer for 200,000 units in 2030, we will be able to (halve the cost) and generate a solid profit.”

But he cautioned “the price of hydrogen remains very high” and Toyota would continue to contribute to the production, transport and use of hydrogen.

Toyota says it is working on a new technology to reduce aerodynamic drag in any shape. Minimising aerodynamic drag would improve BEV performance “beyond customer expectations”. By being able to reduce aerodynamic drag without being restricted by the shape of the car, it was expected to combine attractive design and packaging with aerodynamic performance.

In respect to the Kantar study, meantime, Palmerston North-based TNZ says its feat is significant, in that Toyota is the only car brand in the top 50 and one of only two global brands in the top 20.

Conducted over February and March, the survey considers and gives weighting to aspects such as trust, leadership, fairness and responsibility.

Toyota was third on trust, behind Air New Zealand and Mitre 10. It was also among few brands to achieve improvement on responsibility, again after the national carrier and the home supplies business, and also after outdoors' wear specialist Kathmandu.