Tech heavy approach key to record run

/Mercedes’ unpacks the massive prep that went into its electric car long distance driving feat earlier this week.

PERHAPS thought about Mercedes AMG snatching 25 long distance records on a high-speed bowl in Europe this week has been tempered by knowing the car involved will never reach production.

However, as much as the Concept AMG GT XX seems destined to remain as a test bed, much of the technology it - actually, they, because two cars were involved - used in covering 40,075 kilometres on the legendary Nardò test track in less than eight days seems set to become a showroom certainty. Sooner or later.

That’s got to be appreciated given the strength of the feat. Global headlines were justified. Affalterbach really pushed the limits, with its vehicles sprinting lap after lap, breaking record after record, at a running speed of 300 kmh – for seven days, 13 hours, 24 minutes and seven seconds.

Among the records is the one for the longest distance ever covered by an electric vehicle in 24 hours.

But in this extreme endurance test, the previous benchmark wasn’t just broken once – it was shattered 14 times. Both vehicles exceeded the previous record in every single 24-hour window by an overwhelming margin.

Benz and its performance arm have now unpacked a lot of technical information about the effort.

They say what they are calling an ultimate stress test was only possible thanks to the unmatched endurance capability of its revolutionary drivetrain.

The car is powered by three axial flux motors and a direct-cooled battery – technologies that will enter production next year in the upcoming high-performance architecture AMG.EA.

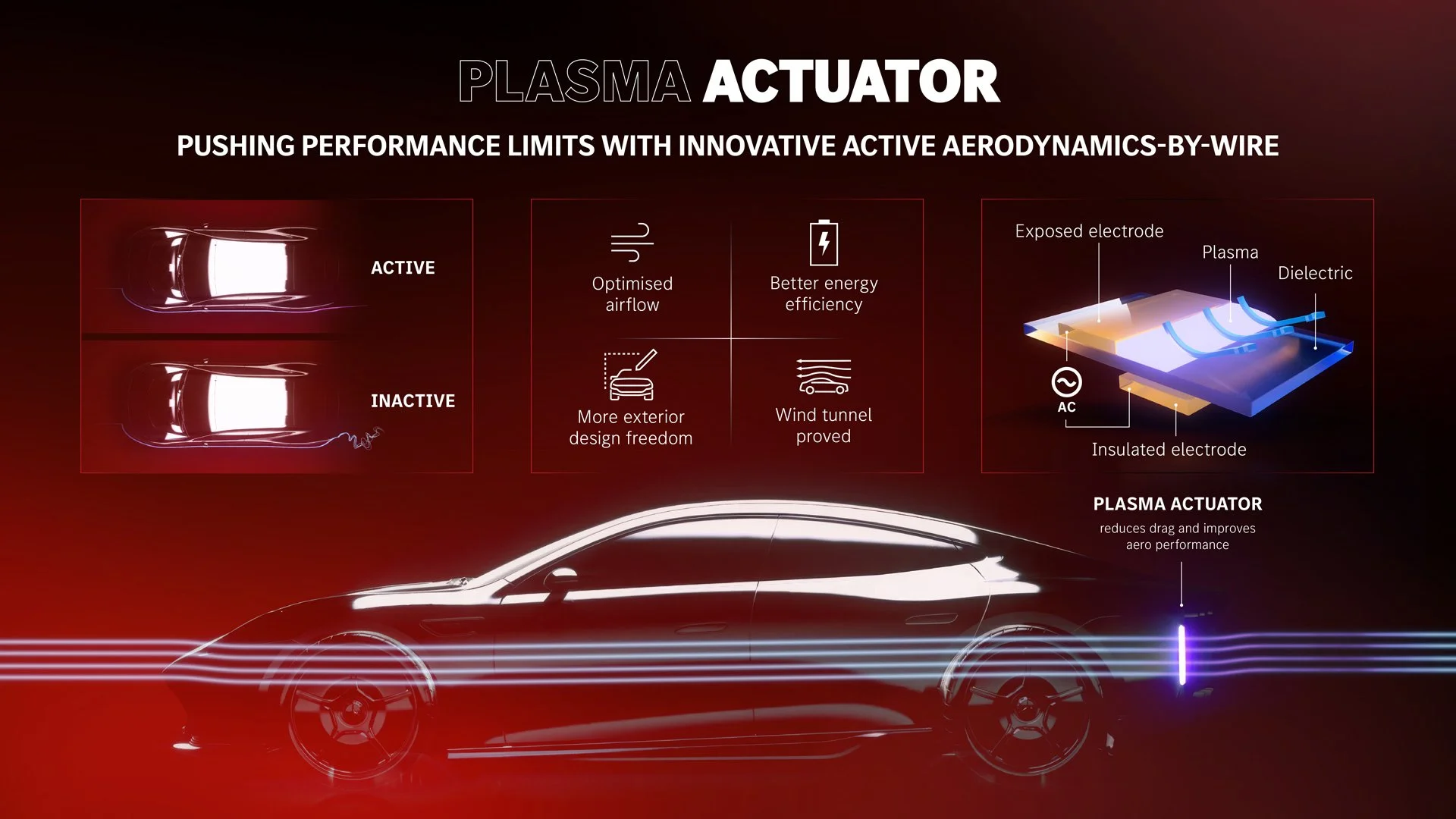

A host of additional, partially production-ready innovations also played a key role in this extreme test. Among them: an integrated cooling concept, sophisticated aerodynamics, and an intelligent operating strategy.

Moreover, the CONCEPT AMG GT XX also introduces a range of innovations in both its exterior and interior.

Highlights include an augmented reality racing helmet, ergonomic 3D seat pads, and novel biotechnology-based materials. Exterior standouts feature illuminated paint segments along the sides, headlight-integrated speakers, and the MBUX Fluid Light Panel at the rear.

The makers say one vital was to keep the high-performance battery and the electric drive units cool. That was delivered by what they have called the “mastermind” of the cooling system, a Central Coolant Hub that sited the high-performance cooling pumps, temperature sensors and valves that required fewer hoses, brackets, clamps, and pumps than conventional solutions – saving both weight and installation space. It was effective enough to allow the motors to consistently run at full capacity.

Another integral element of the cars’ cooling concept is a passive underbody cooling plate at the front. This development from Mercedes‑AMG High Performance Powertrains in England presents as a permanently flowed underbody cooling plate that helps to relieve the main radiator so much that the air control system can remain closed over long periods. This improves energy efficiency and reduces aerodynamic drag.

Aerodynamics also contribute to the high cooling performance. To achieve this, the AIRPANEL air control system – already known from the AMG GT – was further developed. The system ensures an optimal balance between cooling and low drag, operating with movable louvres positioned behind the radiator grille. For the first time, wheel-arch coolers (including fans) were integrated into this system. In normal operation, the louvres remain closed, reducing drag and directing airflow purposefully towards the underbody.

Benz says that, at 300 kmh, roughly 83 percent of the drive energy is needed to overcome aerodynamic drag. “Efficient aerodynamics are therefore particularly crucial in the high-performance segment, especially as the CONCEPT AMG GT XX completed the majority of its extreme endurance test in Nardò at precisely this speed.”

The car was aerodynamically optimised for high speeds and has a coefficient of drag of just 0.19; despite wide high-performance tyres.

Says Benz: “This excellent value had a direct impact on the long-distance drive: At the speeds driven at Nardo, an improvement of just 1 point (Cd reduced by 0.001) has a similar effect on range and efficiency as a weight saving of around 90 kilos. The cars’ active rear spoiler could remain retracted because it generates sufficient downforce through its sophisticated aerodynamics alone.

The cars 20 inch rims were developed just for this event. Benz points out that the aero-carbon claddings differ on the front and rear axles. On the fronts, slats directed the air from the outside to the inside. For the rear, it was the opposite.This improved the air flow around the vehicle and increased driving stability with lower air resistance than fully closed wheels.

Brake cooling could be neglected because deceleration was almost entirely done via recuperation during the drive, up to the pit stop. The car used Michelin high-performance tires, which were developed to combine top performance with maximum efficiency.

In addition to high on-track speeds, high charging speeds were a key success factor. the car charged at an average of around 850 kW, thanks to a newly developed Alpitronic charging station.

To achieve high charging performance and short charging times, the team installed its own High-Power Charging Hub at the test site, including medium-voltage power lines, transformers, and charging stations. The project drew on the expertise of the Mercedes-Benz Charging Unit, responsible for building the global Mercedes-Benz High-Power Charging network.

The construction took just under three months. The hub was designed for three chargers with a total of over 2.5 megawatts. The charger could transmit currents of up to 1000 amps via a standard CCS cable – twice as much as previously possible.

Another important factor in the mission was the intelligent operating strategy, including the Battery Management System (BMS). this based on the Mercedes‑Benz software architecture MB.OS. Experts at Mercedes-AMG in Affalterbach and Mercedes-AMG High Performance Powertrains (HPP) in Brixworth, England, further developed it to keep the battery within its optimal performance window at all times.

Normally internal processes of individual battery cells cannot be measured directly. The team used specially modified cells and sensors in advance to learn how the cells behave during use. The collected data fed directly into the BMS software, enabling precise cell modelling and, for example, further improving charging performance. The simulations created “virtual sensors” derived from the physical measurements. With these virtual sensors, the BMS software could simulate a real-time view into the core of the battery cells during the entire drive. They simulated the drive to determine the ideal driving speed offering the best balance of speed and efficiency. The car’s development team also calculated a driving profile for the individual stints.

A Predictive Performance Manager (PPM) also made a significant contribution to the success. This is a specially developed software of the powertrain. It optimises the energy flow and gives the driver instructions for a particularly performance-efficient driving style. This was done acoustically and visually with signals in a augmented reality helmet and in the instrument panel. The driver also had an instrument array showing current driving time and the number of laps completed since the last charging stop, distance covered, the vehicle’s real-time position on the track, the state of charge (SoC) in percent, and the status of the charging flap. The current driving mode was also displayed.

The steering wheel also offered exciting functionality. The two AMG steering wheel buttons, familiar from AMG production models, were configured exclusively for the record run. The left button controlled the setting of the next recuperation point, while the right button allowed manual adjustment of the active louvers and selection of the number of laps before the next charging stop.

The upper rim of the steering wheel featured eight LEDs providing additional information. Depending on the number of LEDs illuminated, they indicated the progress of certain functions. During the charging stop, the LEDs were blue until the desired state of charge is reached. Green LEDs were the signal to start driving, red lights signalled a driver to wait. During driving, white LEDs prompted “lift and coast,” while blue lights indicated recuperation.