How Ford torture tests the Mustang Mach-E

/Car makers are often asked if electric vehicles are as durable as their combustion engine counterparts.

EVER wondered how durable an electric car is?

Ford has found need to demonstrate the toughness of its primary electric car, the Mustang Mach-E, with a series of tests that, it believes, will settle ‘what if’ qualms and to debunk scepticism from the anti-EV quarter.

The factory’s torture testing for a model that is on the New Zealand distributor’s wish list – but, at present point of time, with no local launch timing available – is intriguing.

In addition to the obvious rigours, such as how it copes with repeated running on unsealed surfaces, the car has also been put through other challenges that are designed to stress it beyond typical consumer use. Repeated extreme car washes. How it stands up to power sprayers and … robotic butts.

The aim of a schedule shown in today’s video is to give the confidence to its prospective buyers to take a leap to electric.

“We have gone to great lengths to subject Mustang Mach-E to extreme tests – stressing it much more than a typical consumer would – to help ensure it is ready to face the rigour of the open road,” says the car’s chief programme engineer, Donna Dickson.

Playing with water is an important factor, according to information shared to the brand’s customer base in Europe and the United Kingdom, where right-hand drive sales have begun.

Around 13 percent of Europeans are unsure if electric vehicles can get wet while being driven in the rain – much less be able to go through a full car wash. Ford subjected the car to 60 passes through a brutal, suds-free automatic conveyor wash complete with sprayers, brushes, and dryers – the equivalent of a wash every two weeks for more than two years.

To help test against leaks and other exterior damage that could be caused by water, the team blasted the door frames, trim, cowling, badges, headlamps, taillamps and adhesives of the Mustang Mach-E with a high-pressure water sprayer. The sprayer is capable of pressures up to 1,700 PSI and a temperature of 60 degrees Celsius and is sprayed at a distance of just 30 centimetres away from the vehicle’s exterior. That kind of pressure can remove oil stains from driveways when used with detergents.

Ford tested for just about anything customers might subject their seats to – especially their derrieres. Ford engineers studied varying weight loads on the seats using a wide range of human body types. The team does this by programming a robotic butt form, or “robutt” (above), to simulate a person getting in and out of their Mustang Mach-E – at least 25,000 times.

They also extensively tested the vehicle’s ActiveX seating material to withstand daily use and abuse. This included chemical testing to help ensure products like hand sanitizer do not deteriorate the material, abrasion testing to ensure the finish stays put after simulating a 10-year use cycle, and flexing the seating material 100,000 times to assess its resistance to cracking.

A cracked phone screen is never fun, but a cracked touchscreen – especially one with as much functionality as the screen in the Mach-E — is unacceptable, the brand says. The 15.5-inch touch screen in the 2021 Mustang Mach-E uses a special application of Dragontrail glass to ensure its durability. It sits on top of a high-strength magnesium mounting that is able to withstand being pulled or bumped.

“The screen in the Mustang Mach-E is so crucial to the driving experience. It’s the centrepiece of the interior and people’s eyes just naturally go right to it,” said Dickson.

“We knew we had to go above and beyond to make sure it is durable enough to withstand daily customer interactions — think purses and bags hitting it, pets bumping into it, children playing with it and so on. You need that deep customer understanding to identify the potential issues and work to prevent them.”

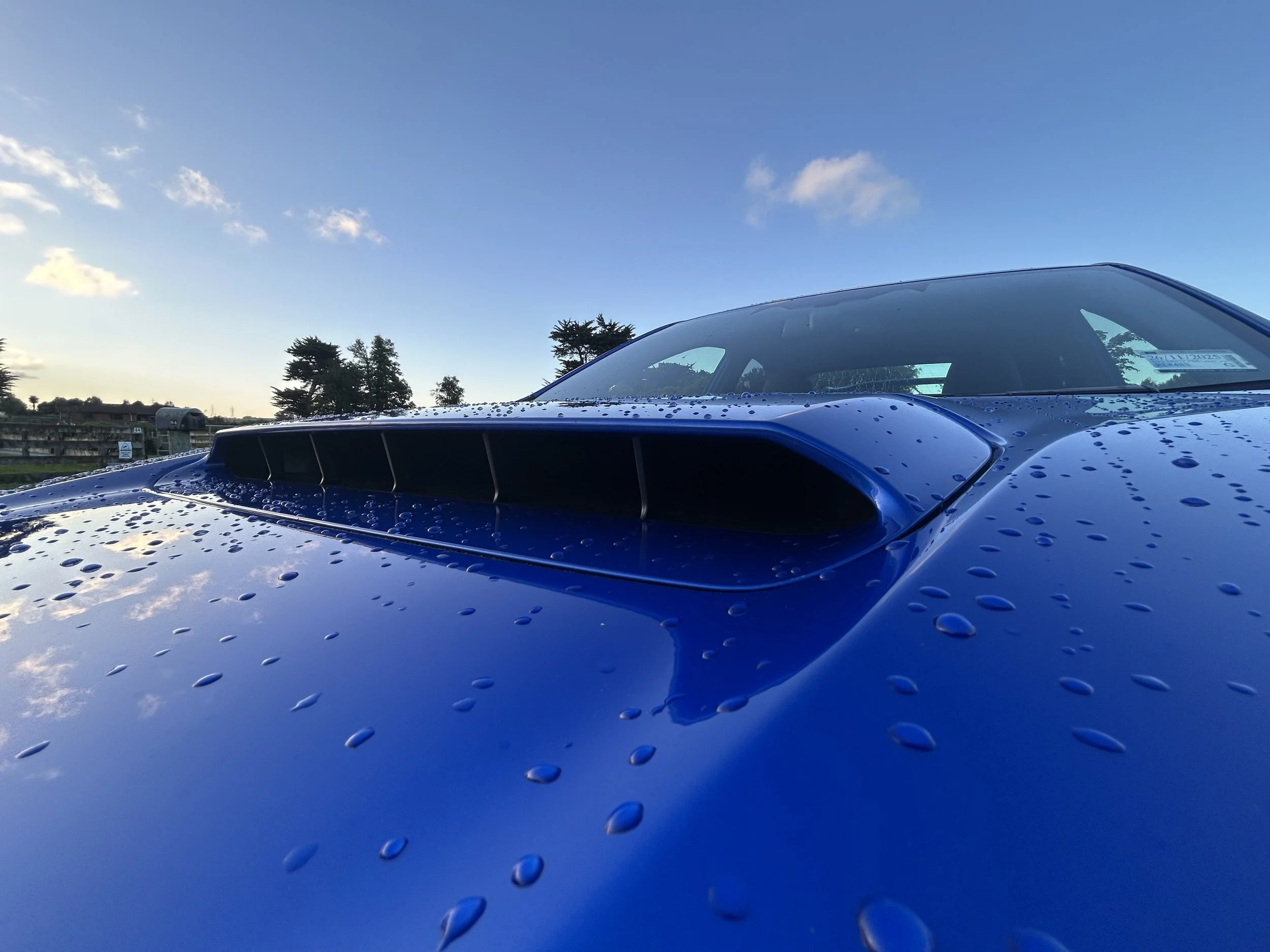

Customers should be confident that they can drive their vehicle where the seal ends and gravel roads begin, and not come back with a new “speckled” paint job

To do this, Ford engineers subjected Mustang Mach-E to almost 500kms of stone-chip testing on gravel roads to evaluate damage caused to body paint by small rocks and cinder.

Ford used two different grades of gravel stones to test as professional drivers fishtailed Mustang Mach-E over a long stretch of scattered gravel at 100kmh nearly 200 times.

Once the first test was completed, the team then swapped the gravel for an even sharper grade of stone and repeated the test all over again.

“Electric vehicles shouldn’t be limited to nicely paved city streets and suburbia,” said Dickson “We tested Mustang Mach-E so that customers can confidently live on or adventure down gravel roads and not worry about their paint easily chipping.”